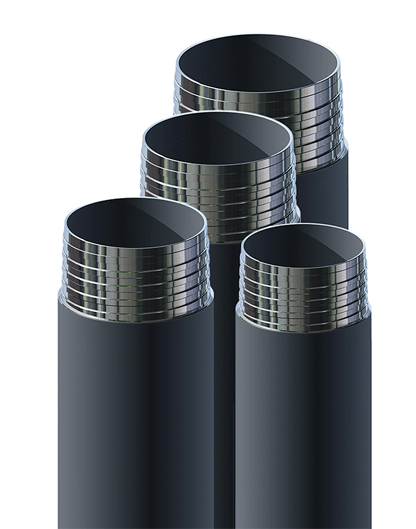

Wireline Drill Rods

Ensure maximum productivity and more cost-effective drilling with Drillers Edge wireline coring rods, designed for optimum joint integrity, torque and pullback capacity, and longer drill string life.

Mining Drilling Fluids & Additives

- Bentonite Products - Mineral Exploration

- Cements & Grouts - Mineral Exploration

- General Chemicals - Mineral Exploration

- Greases, Lubricants & Compounds - Mineral Exploration

- Lost Circulation Materials - Mineral Exploration

- Mineral Processing - Flotation Products

- Polymer Additives - Mineral Exploration

- Specialty Products - Mineral Exploration

- Thinners/Dispersants - Mineral Exploration

- Waste Treatment - Mineral Exploration

- Weighting Materials - Mineral Exploration

Oilfield Drilling Fluids

- Alkalinity Controllers - Oil & Gas

- Bactericides - Oil & Gas

- Calcium Removers - Oil & Gas

- Corrosion Inhibitors - Oil & Gas

- Emulsifiers - Oil & Gas

- Filtrate Reducers - Oil & Gas

- Flocculants - Oil & Gas

- Lost Circulation Materials - Oil & Gas

- Lubricants - Oil & Gas

- Oil and Gas Defoamers

- Polymer Breakers - Oil & Gas

- Shale Inhibitors - Oil & Gas

- Specialty Additives - Oil & Gas

- Surfactants - Oil & Gas

- Thinners/Dispersants - Oil & Gas

- Viscosifiers - Oil & Gas

- Weighting Materials - Oil & Gas

Trenchless and Technical Drilling Fluids & Additives

- Directional Drilling Fluids & Additives

-

Environmental and Geotechnical Drilling Fluid Additives

- Bentonite Products - Geotechnical & Environmental

- Cements & Grouts - Geotechnical & Environmental

- Drilling Foaming Agents/Surfactants

- General Chemicals - Geotechnical & Environmental

- Greases, Lubricants & Compounds - Geotechnical & Environmental

- Lost Circulation Materials - Geotechnical & Environmental

- Polymer Additives - Geotechnical & Environmental

- Specialty Products - Geotechnical & Environmental

- Thinners/Dispersants - Geotechnical & Environmental

- Waste Treatment - Geotechnical & Environmental

- Weighting Materials - Geotechnical & Environmental

-

Geothermal Drilling Fluid Additives

- Bentonite Products - Geothermal

- Cements & Grouts - Geothermal

- General Chemicals - Geothermal

- Greases, Lubricants & Compounds - Geothermal

- Lost Circulation Materials - Geothermal

- Polymer Additives - Geothermal

- Specialty Products - Geothermal

- Surfactants/Foam - Geothermal

- Thinners/Dispersants - Geothermal

- Weighting Materials - Geothermal

- Infrastructure Drilling Fluid Additives

-

Oil Sands Coring Drilling Fluids & Additives

- Bentonite Products - Oil Sands Coring

- Cements & Grouts - Oil Sands Coring

- General Chemicals - Oil Sands Coring

- Greases, Lubricants & Compounds - Oil Sands Coring

- Lost Circulation Materials - Oil Sands Coring

- Polymer Additives - Oil Sands Coring

- Specialty Products - Oil Sands Coring

- Thinners/Dispersants - Oil Sands Coring

- Weighting Materials - Oil Sands Coring

-

Tunneling Drilling Fluid Additives

- Bentonite Products - Tunneling

- Flocculants & Coagulants - Tunneling

- General Chemicals - Tunneling

- Greases, Lubricants & Compounds - Tunneling

- Lost Circulation Materials - Tunneling

- Polymer Additives - Tunneling

- Specialty Products - Tunneling

- Surfactants/Foam - Tunneling

- Thinners/Dispersants - Tunneling

- Waste Treatment - Tunneling

-

Water Well Drilling Fluids & Additives

- Bentonite Products - Water Well

- Cements & Grouts - Water Well

- General Chemicals - Water Well

- Greases, Lubricants & Compounds - Water Well

- Lost Circulation Materials - Water Well

- Polymer Additives - Water Well

- Production Chemicals - Water Well

- Specialty Products - Water Well

- Surfactants/Foam - Water Well

- Thinners/Dispersants - Water Well

- Weighting Materials - Water Well

Oilfield Cement Additives

- Accelerators

- Acidizing Specialty Additives

- Alkalinity Controllers

- Bactericides

- Buffers/pH Adjusters

- Calcium Removers

- Cement Foamers

- Cements

- Corrosion Inhibitors

- Crosslinkers

- Defoamers/Antifoamers

- Evaporate Stabilizers

- Extenders

- Lost Circulation Materials

- Retarders

- Shale Inhibitors/Clay Stabilizers

- Specialty Additives

- Thinners/Dispersants

- Viscosifiers

- Weighting Materials

Industrial Tooling Consumables & Accessories

Home » Products » Wireline Drill Rods, Casing, and Adapters » Wireline Drill Rods

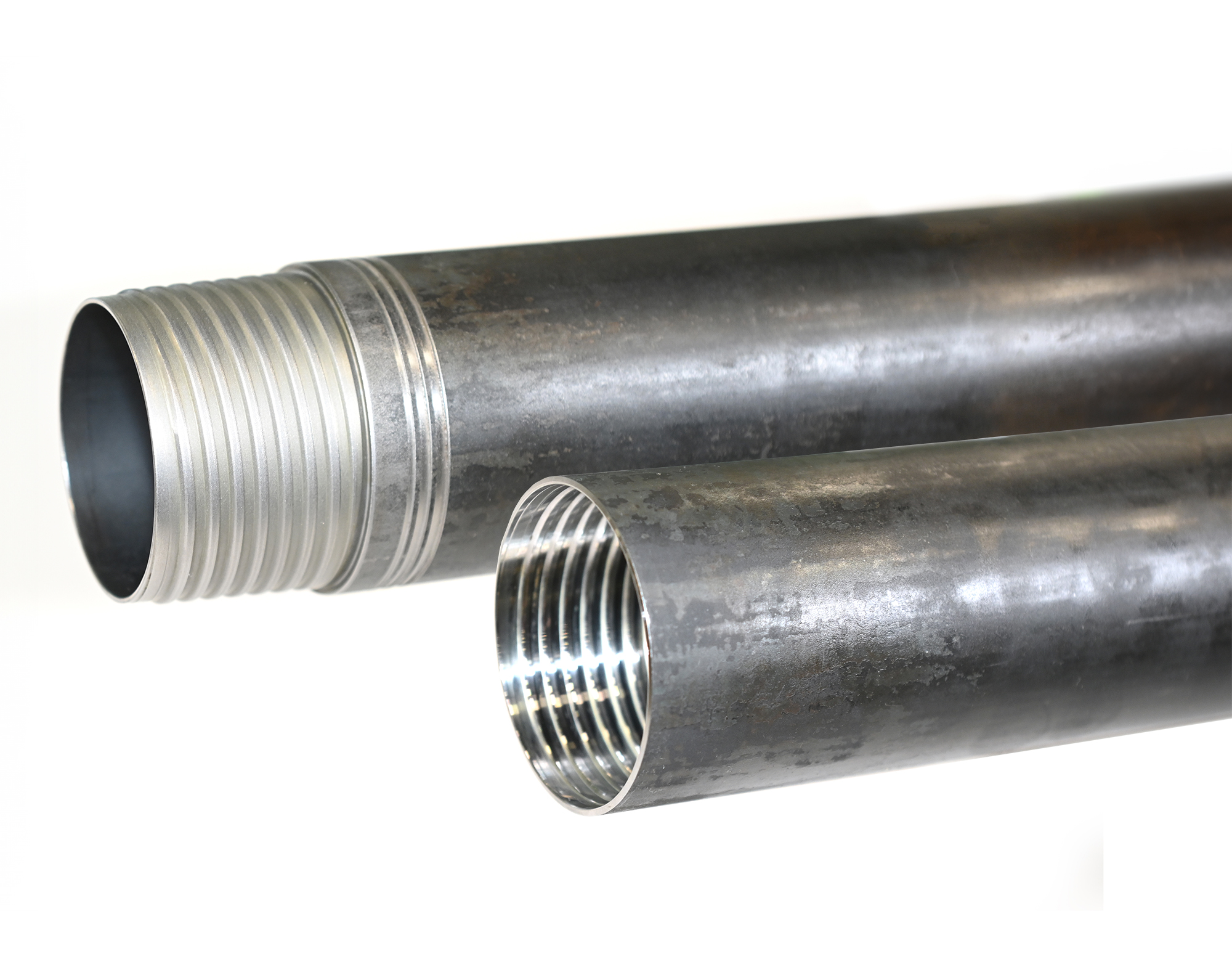

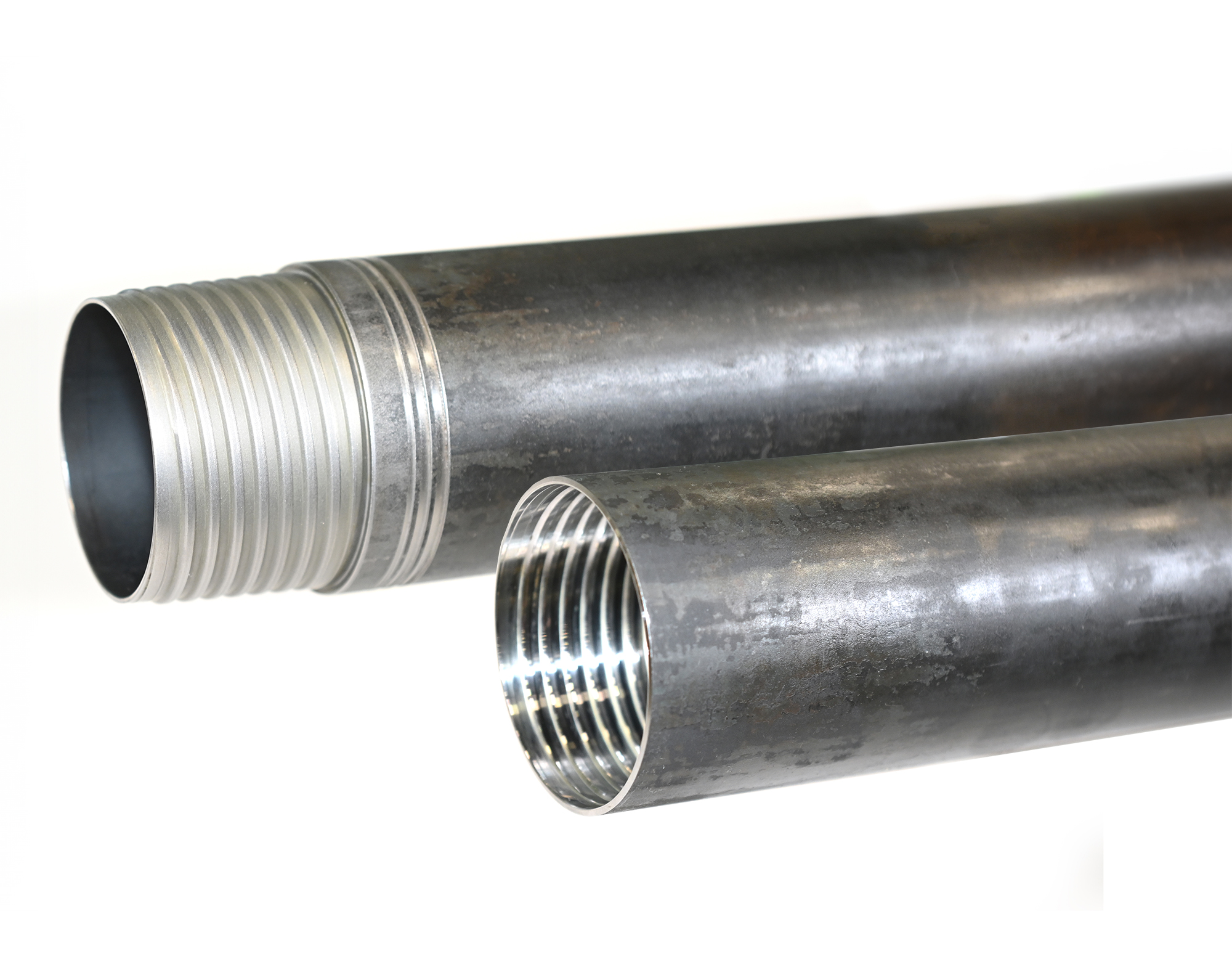

Drillers Edge Wireline Drill Rods by Di-Corp: When Quality Matters

Manufactured to the highest standards of quality and precision, Di-Corp offers drill rod solutions that improve your bottom line, increases your competitiveness, and enhances your drilling performance. Our outstanding performance in the field starts with extremely high standards at every stage of manufacturing. We begin with the highest quality steel and steel alloy tubing that meets our demanding specifications for concentricity. Then

we use our proprietary approach to heat treating to virtually eliminate internal mechanical stress within the rod, making it more resilient to downhole forces.

Our dedication to quality results in drill rods that provide:

- More even pin and box wear

- Greater resilience during wedging or deviated drilling

- Superior drill string life compared to major competitors under the same conditions

- Max rod life, max joint strength, max depth capacity, and max efficiency with our patented next generation drill rod: the S-Maxx™.

Our Featured Wireline Drill Rod Products

S-Maxx™ Wireline Drill Rod

Thread Shield

Di-Corp’s Superior Wireline Drilling Rod Lineup for Wireline Coring

Drillers Edge coring rods have earned a reputation for outstanding reliability, achieving up to two othe normal drill string life of major competitors under the same conditions. Additionally, our drill rods are manufactured from the highest quality steel and steel alloy and are processed with an additional stress-relief heat treatment to eliminate bent rods.

The Di-Corp wireline coring rod lineup is offered in B, N, H and P sizes (Note: S-Maxx is not available in P size).

Drillers Edge Coring Rods brochure:

English | Français | Español

Deep Hole Wireline Drill Rod

Drill deeper and longer with Di-Corp’s advanced ‘D’ thread deep hole wireline drill rods.

LITE Wireline Drill Rods

The variable wall thickness of Drillers Edge LITE drill rods helps reduce drill string weight by as much as 23 percent for more efficient drilling without sacrificing joint strength or rod life.

R™ Reverse Flank Wireline Drill Rod

Our R™ reverse flank thread form delivers at least 6% more pullback strength than the nearest major competitor for greater joint strength and depth capacity.

S-Maxx™ Wireline Drill Rod

Next generation drill rod for modern drilling challenges. Take your drilling to the Maxx.

Standard Wireline Drill Rod

Di-Corp’s machining and manufacturing of this industry-standard thread form ensure no distortion for a truer fit for increased depth capacity, less bulging and breaking, and reduced fluid loss.

What Our Customers Say About Drillers Edge Drill Rods

“Di-Corp’s Drillers Edge rods performed extraordinary well on our directional projects globally. Their rods hold up to the extremes of down hole deviation time and time again.”

Nils Ivar Klinge Iversen

Chief Executive Officer

AZIWELL

“I am always happy to see Di-Corp rods at a drill site.”

Operations Manager

TECH Directional Services

“I would recommend Di-Corp drill rods to any contractor.”

Surface Operations Superintendent

Orbit Garant Drilling

Why Choose Di-Corp

Di-Corp knows drilling. Drawing on decades of field experience, we manufacture and distribute the highest quality, top-performing drilling tools and consumables favoured by diamond core drillers worldwide. Additionally, we offer technical field support and fluids engineering with access to 24/7 customer-focused assistance.

Industry-Leading Manufacturer and Distributor

Intense Quality Control

Outstanding Drill Rod Performance

Frequently Asked Questions

What thread forms do Drillers Edge drill rods have?

Available thread forms on our drill rods include the industry standard “WL” thread, the “R” thread – our version of the reverse flank thread form that is popular in the market today, our patented “D” thread, designed especially for deep hole drilling, and S-Maxx – a next gen drill rod designed to meet the needs of today’s modern driller. The threads on every single rod we manufacture are gauged after machining, ensuring that the threads on both the pin and box end are perfectly machined to provide a quality joint fit and smoother make-up and breakout of the drill rod string.

How can drillers easily identify one thread form from another in the field?

Di-Corp drill rods come with engraved indicator grooves on the

outside of the rod to quickly identify the thread. One groove for

R thread, two grooves for D thread, three grooves for S-Maxx, and no grooves for standard wireline.

What sizes do Drillers Edge Drill Rods come in?

Drillers Edge coring rods are manufactured in a large quantity of industry-standard diameters, including B, N, H, and P, in 3-meter and 1.5-meter lengths. However, not all rods are available in all sizes and lengths – details are available in each product page.

- CONTACT US

Improve Drilling Operations With Drillers Edge Drill Rods

Di-Corp’s Drillers Edge drill rods are earning a global reputation for being extremely reliable and providing long-lasting performance under some of the harshest conditions. Browse through our drill rods and request a comprehensive quote for your drilling project today.

"*" indicates required fields