Cements & Grouts - Oil Sands Coring

Mining Drilling Fluids & Additives

- Bentonite Products - Mineral Exploration

- Cements & Grouts - Mineral Exploration

- General Chemicals - Mineral Exploration

- Greases, Lubricants & Compounds - Mineral Exploration

- Lost Circulation Materials - Mineral Exploration

- Mineral Processing - Flotation Products

- Polymer Additives - Mineral Exploration

- Specialty Products - Mineral Exploration

- Thinners/Dispersants - Mineral Exploration

- Waste Treatment - Mineral Exploration

- Weighting Materials - Mineral Exploration

Oilfield Drilling Fluids

- Alkalinity Controllers - Oil & Gas

- Bactericides - Oil & Gas

- Calcium Removers - Oil & Gas

- Corrosion Inhibitors - Oil & Gas

- Emulsifiers - Oil & Gas

- Filtrate Reducers - Oil & Gas

- Flocculants - Oil & Gas

- Lost Circulation Materials - Oil & Gas

- Lubricants - Oil & Gas

- Oil and Gas Defoamers

- Polymer Breakers - Oil & Gas

- Shale Inhibitors - Oil & Gas

- Specialty Additives - Oil & Gas

- Surfactants - Oil & Gas

- Thinners/Dispersants - Oil & Gas

- Viscosifiers - Oil & Gas

- Weighting Materials - Oil & Gas

Trenchless, HDD, & Infrastructure Drilling Fluids and Additives

- Directional Drilling Fluids & Additives

-

Geothermal Drilling Fluid Additives

- Bentonite Products - Geothermal

- Cements & Grouts - Geothermal

- General Chemicals - Geothermal

- Greases, Lubricants & Compounds - Geothermal

- Lost Circulation Materials - Geothermal

- Polymer Additives - Geothermal

- Specialty Products - Geothermal

- Surfactants/Foam - Geothermal

- Thinners/Dispersants - Geothermal

- Weighting Materials - Geothermal

- Infrastructure Drilling Fluid Additives

-

Tunneling Drilling Fluid Additives

- Bentonite Products - Tunneling

- Flocculants & Coagulants - Tunneling

- General Chemicals - Tunneling

- Greases, Lubricants & Compounds - Tunneling

- Lost Circulation Materials - Tunneling

- Polymer Additives - Tunneling

- Specialty Products - Tunneling

- Surfactants/Foam - Tunneling

- Thinners/Dispersants - Tunneling

- Waste Treatment - Tunneling

Oilfield Cement Additives

- Accelerators

- Acidizing Specialty Additives

- Alkalinity Controllers

- Bactericides

- Buffers/pH Adjusters

- Calcium Removers

- Cement Foamers

- Cements

- Corrosion Inhibitors

- Crosslinkers

- Defoamers/Antifoamers

- Evaporate Stabilizers

- Extenders

- Lost Circulation Materials

- Retarders

- Shale Inhibitors/Clay Stabilizers

- Specialty Additives

- Thinners/Dispersants

- Viscosifiers

- Weighting Materials

Oil Sands Fluids, Additives, Consumables, and Accessories

- Accessories & Consumables

- Bentonite Products - Oil Sands Coring

- Cements & Grouts - Oil Sands Coring

- General Chemicals - Oil Sands Coring

- Greases, Lubricants & Compounds - Oil Sands Coring

- Lost Circulation Materials - Oil Sands Coring

- Polymer Additives - Oil Sands Coring

- Sand – Oil Sands Coring

- Specialty Products - Oil Sands Coring

- Thinners/Dispersants - Oil Sands Coring

- Weighting Materials - Oil Sands Coring

Tooling, Consumables and Accessories

Home » Products » Oil Sands Fluids, Additives, Consumables, and Accessories » Cements & Grouts - Oil Sands Coring

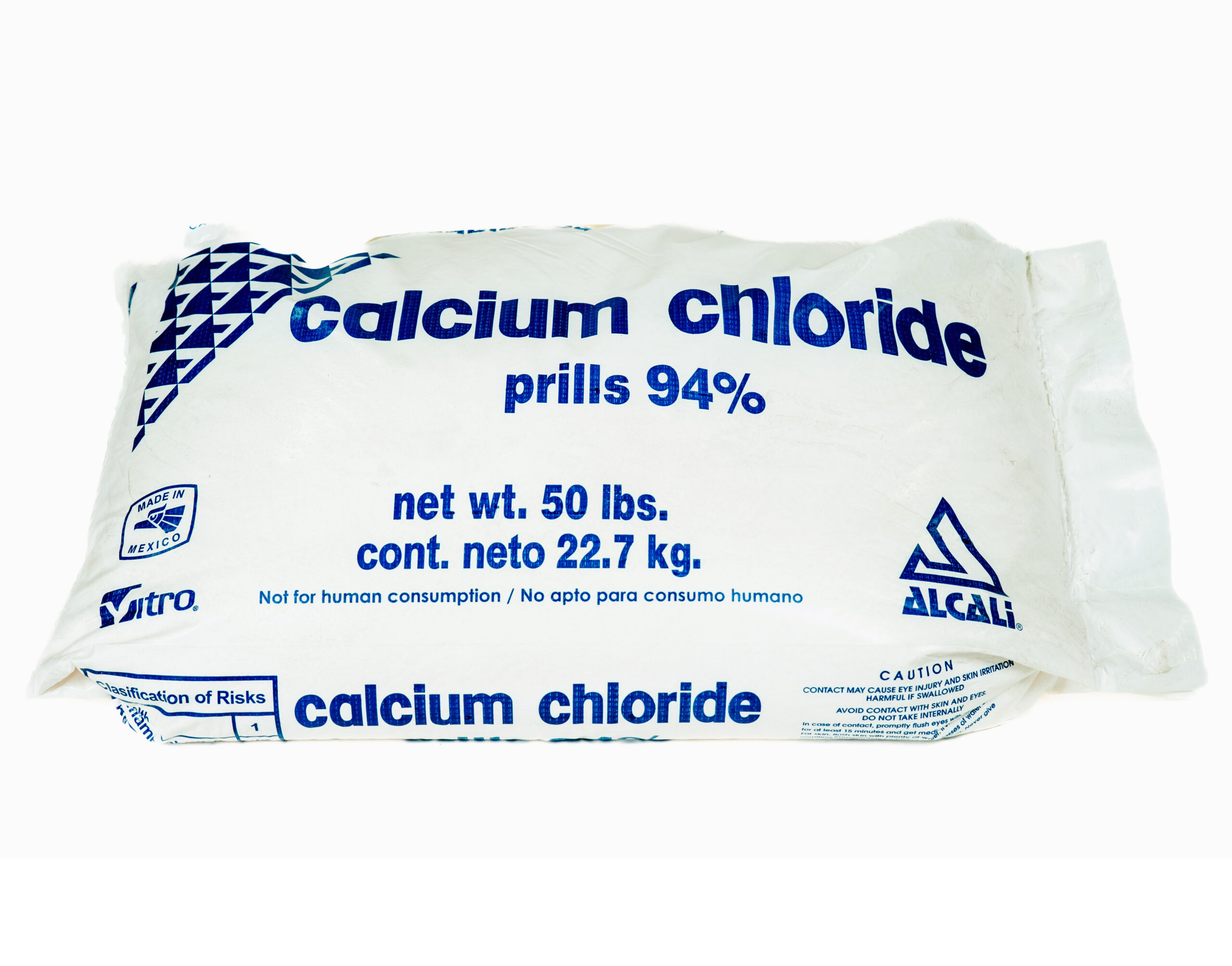

Calcium Chloride 94-97% – Mini Prills

An anhydrous pellet form of calcium chloride (CaCl2). It is the most widely used and most effective of all cement accelerators in drilling fluid additives. Normally 1 to 3% calcium chloride based on the cement is used. Calcium chloride is added to drilling fluids to shorten the setting time and/or accelerate the hardening process. It can also limit corrosion and improve the performance of mud systems.

Enviroplug® Grout

Enviroplug® Grout is a bentonite formula designed for diverse applications, serving as a water well-grouting fluid, drill hole abandonment fluid, and grout for geotechnical monitoring wells post-casing placement.

Grout-Well® and Grout-Well® DF

Grout-Well® and Grout-Well® DF are one-step bentonite grouting materials designed to achieve low permeability seals in water wells, monitor wells, geotechnical borings, and heat pump holes.

Oilwell ‘G’ Cement

Earth Pro Oilwell ‘G’ Cement is manufactured according to rigorous API standards with respect to setting time, compressive strength, free water content, and various physical and chemical parameters. Specifically for oil industry applications where wellbore temperatures stay below 100°C BHST, this cement variant maintains reliability and performance in oilfield operations.

Thermal 40 Cement

Earth Pro Thermal 40 Cement is typically used where wellbore temperatures exceed 115°C due to well depth or physical treatment (i.e. steam flooding). This cement can overcome high-temperature degradation, meets the ERCB Directive, and is typically used on a small scale for dump-bail treatment.

- Contact Us

Learn More About Our Drilling Equipment

& Supplies

"*" indicates required fields